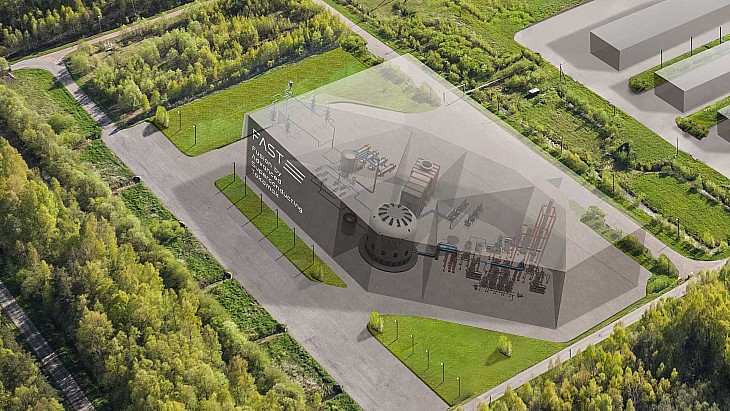

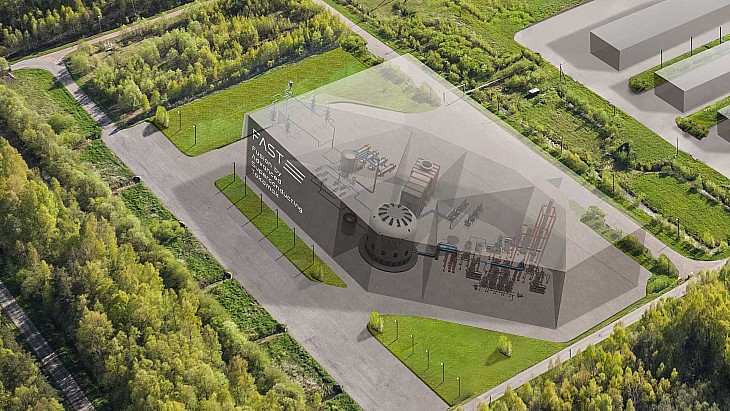

(Image: Kyoto Fusioneering) (Image: Kyoto Fusioneering)The Conceptual Design Report has been put together in the year since the project's launch in November 2024, and involved the two companies and researchers and experts from a number of Japanese universities and public institutions, as well as support from a number of other Japanese companies. The Fusion by Advanced Superconducting Tokamak (FAST) device, to be sited in Japan, aims to generate and sustain a plasma of deuterium-tritium (D-T) reactions, demonstrating an integrated fusion energy system that combines energy conversion including electricity generation and fuel technologies. The project will employ a tokamak configuration, chosen for its well-established data and scalability. Targeting a power generation demonstration by the end of the 2030s, FAST will address remaining technical challenges en route to commercial fusion power plants. The FAST Project Office notes that power generation refers to producing energy from fusion reactions, but does not imply net positive power production where electricity output exceeds electricity consumption. The project team said the conceptual design work involved "designing the fusion energy plant for power generation demonstration, assessing technical and engineering feasibility, clarifying the project direction, conducting safety and economic evaluations, and defining the plant's fundamental design specifications". "With the completion of the conceptual design phase, the project will now shift to engineering design, accelerated engineering R&D, and will proceed with site selection, site preparation, regulatory approvals, and the procurement of long-lead items, with the aim of construction after 2028," it said. Kiyoshi Seko, CEO of Starlight Engine Ltd and President and COO of Kyoto Fusioneering Ltd, said: "Completing the conceptual design in just one year is a result of Japan's decades of research achievement. FAST is now moving into the engineering design phase. We will harness the strength of Japan's manufacturing industry and accelerate the project with a sense of urgency." Satoshi Konishi, co-founder and CEO of Kyoto Fusioneering, said: "First and foremost, it's a great achievement to complete the conceptual design activities within the planned one-year timeframe. We succeeded in creating an innovative design that incorporates new technologies essential for commercial plants, such as high-temperature superconducting magnets, liquid breeding blanket systems, and highly efficient tritium fuel cycle systems, by mobilising domestic experts. Preparations for safety design, regulatory approvals, and site selection are steadily progressing. In the next engineering design phase we expect to fully leverage our strengths in plant engineering and our broad network across diverse industries, including finance and construction." Kenzo Ibano, Assistant Professor, Osaka University, said: "Thanks to the power of industry-academia collaboration, we have successfully produced Japan’s first CDR for a power generation demonstration project. Working alongside researchers with decades of experience and private-sector partners in driving this project forward is both stimulating and rewarding, giving a strong sense of mission." The Conceptual Design Report is due to be presented at the 42nd Annual Meeting of the Japan Society of Plasma Science and Nuclear Fusion Research being held from 1 December.Other academics and businesses participating in and supporting the FAST project include Professor Akira Ejiri, University of Tokyo and Professor Takaaki Fujita, Nagoya University, as well as Sumitomo Mitsui Banking Corporation, Electric Power Development (J-Power), JGC JAPAN Corporation, Hitachi, Fujikura, Furukawa Electric, Marubeni Corporation, Kajima Corporation, Kyocera, Mitsui & Co., Mitsui Fudosan, and Mitsubishi Corporation. Conceptual design completed for Japan's FAST fusion demo project |

Korean designed nuclear-powered LNG carrier certified (2026-01-07T12:11:00+05:30)

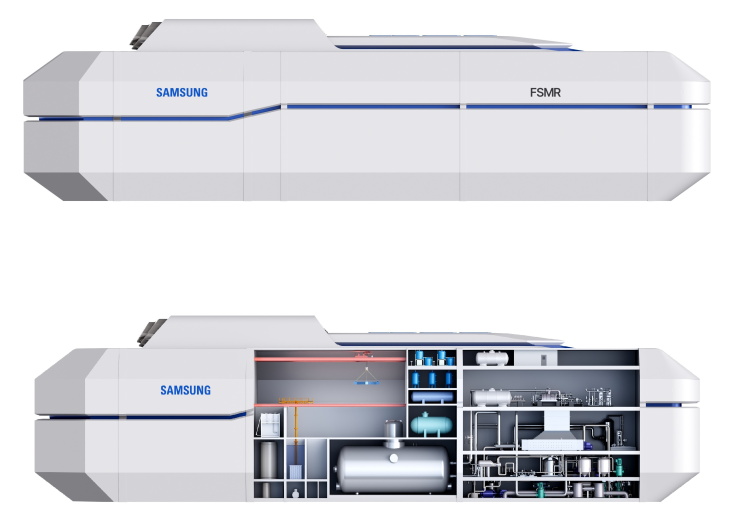

_86891.jpg) Samsung announced the certification at Gastech 2025 in Milan (Image: Samsung Heavy Industries) Samsung announced the certification at Gastech 2025 in Milan (Image: Samsung Heavy Industries)Samsung Heavy Industries has obtained Approval in Principle from the American Bureau of Shipping and the Liberian Registry for a 174,000-cubic-metre liquefied natural gas carrier powered by a small modular molten salt reactor. The molten salt reactor (MSR) for the LNG carrier is being conceptually designed jointly by Samsung Heavy Industries and the Korea Atomic Energy Research Institute (KAERI). The MSR is designed to have a capacity of 100 MWt and to eliminate the need for fuel replacement during the life of the vessel even if only one unit is installed. "The MSR method has the characteristics of increased stability and excellent energy efficiency by using molten salt (liquid nuclear fuel) that integrates nuclear fuel and coolant," said Samsung Heavy Industries, which has been researching nuclear technology for many years, including various concepts for floating nuclear power plants. As part of the Novel Concept Class Approval process, the American Bureau of Shipping (ABS) grants an Approval in Principle (AIP) at an early conceptual design phase to assist the client in demonstrating project feasibility to its project partners and regulatory bodies. AIP confirms that the proposed novel concept that includes the new technology complies with the intent of the most applicable ABS Rules and Guides as well as required appropriate industry codes and standards, subject to a list of conditions.  The MSR-powered LNG carrier concept (Image: KAERI) KAERI said obtaining AIP for the conceptual design "is the first step toward moving forward with actual ship development". In October last year, ABS released a study of a small modular reactor on a standard LNG carrier. ABS said the study was designed to help industry "better understand the feasibility and safety implications of nuclear propulsion and to support future development projects". The study considered the impact of a high-temperature, gas-cooled reactor on the design, operation and emissions of a 145,000-cubic-metre LNG carrier design . The report noted that LNG carrier vessels are increasing in demand as the international LNG trade remains important for global energy security. LNG is stored on board in large cryogenic tanks that maintain natural gas (primarily methane) in a liquid state around -165°C. The typical energy demand for LNG carriers is between 30 to 75 MW. "Nuclear power would be an ideal means of drastically abating shipping emissions, but significant hurdles remain in public perception and international regulations before this can be achieved," the report said. In August 2022, ABS announced it had been awarded a contract by the US Department of Energy (DOE) to research barriers to the adoption of advanced nuclear propulsion on commercial vessels. Working with support from DOE's National Reactor Innovation Center, based at Idaho National Laboratory, ABS is developing models of different advanced reactor technologies for maritime applications and developing an industry advisory on the commercial use of modern nuclear power.The shipping industry consumes some 350 million tonnes of fossil fuel annually and accounts for about 3% of total worldwide carbon emissions. In July 2023, the shipping industry, via the International Maritime Organization, approved new targets for greenhouse gas emission reductions, aiming to reach net-zero emissions by, or around, 2050. Korean designed nuclear-powered LNG carrier certified |

Gas-powered muscle cars drive into the sunset & turns electric (2026-01-01T13:33:00+05:30)

Tim Kuniskis, head of Dodge Brand talks about the Dodge Charger Daytona SRT concept that was unveiled, Wednesday, Aug. 17, 2022, in Pontiac, Mich. (AP Photo) Tom Krisher, The Associated Press: Thundering gas-powered muscle cars, for decades a fixture of American culture, will be closing in on their final Saturday-night cruises in the coming years as automakers begin replacing them with super-fast cars that run on batteries. Stellantis’ Dodge brand, long the performance flag-bearer of the company formerly known as Fiat Chrysler, is officially moving toward electricity. On Wednesday night, Dodge unveiled a battery-powered Charger Daytona SRT concept car, which is close to one that will be produced in 2024 as the sun sets on some petroleum models. Stellantis says it will stop making gasoline versions of the Dodge Challenger and Charger muscle cars and the Chrysler 300 large car by the end of next year. The Canadian factory that makes them will be converted to electric vehicles. Other automakers are moving — or have moved — in the same direction. General Motors has said it will build an all-electric Chevrolet Corvette. Tesla says its Model S Plaid version is the fastest production vehicle made, able to go from zero to 60 mph (97 kilometers per hour) in under 2 seconds. Audi, Mercedes, Porsche and other European automakers already have high-performance electric models on sale. And Polestar, an electric-performance spinoff from Volvo, just announced a new Polestar 6 roadster for 2026. One reason for the industry shift is that electric vehicles are simply faster off the starting line. Their handling is typically better, too, because their heavy batteries create a low center of gravity. Stricter government pollution requirements are another factor, too. As automakers in the U.S. face more stringent fuel-economy requirements adopted by the Biden administration and produce a broader range of EV vehicles, they will have to jettison some of their gas-fueled muscle-car models. Tim Kuniskis, CEO of the Dodge brand, said the possibly of government fines for not meeting gas-mileage requirements hastened the shift to the electric Charger. “Compliance fines and things like that associated with a big cast-iron supercharged V8, yes, it’s tough,” he said. Still, it will take a few years for the gas-powered classics to go away. “Over the next several years, I think we’ll continue to have some internal combustion stuff, probably through most of the decade,” said Sam Abuelsamid, a research analyst at Guidehouse Insights. “But increasingly, the focus is going to be on the electric ones.” Under new gas-mileage standards that were unveiled in April, the fleet of new vehicles will have to average around 40 miles per gallon in 2026, up from 25.4 mpg now, the EPA says. The standards are likely to become even stronger in the future, a trend that will compel U.S.-based automakers to shed some gasoline muscle cars if they are to avoid fines. Of all major automakers, the EPA says, Stellantis had the lowest average fuel economy — 21.3 miles per gallon — and the highest average carbon dioxide emissions. So the company likely will have to eliminate some models to avoid fines. Its limited-edition Charger SRT Widebody, with a supercharged 6.2-liter Hemi Hellcat V-8, for instance, gets only 12 mpg in city driving and 21 mpg on the highway. To many gearheads, the thought of a muscle car without noise and smells is heresy. But Kuniskis says Dodge is working hard to make the electric experience match internal combustion. The Charger, he said, will generate its own air flow to make an exhaust noise that rivals gas performance cars. And the transmission will shift gears. When the electric Charger was driven through a garage door and entered a building Wednesday night at a racetrack in Pontiac, Michigan, it roared just like a gas muscle car. Electric vehicles, Kuniskis said, have the potential to perform better than gas muscle cars with fast acceleration. But he said they are kind of sterile. “It doesn’t have the emotion. It doesn’t have the drama. It doesn’t have the kind of dangerous feeling that ICE (an internal combustion engine) has when it’s loud and rumbling and shifting and moving the car around.” Kuniskis wouldn’t say how fast the electric Charger will go from zero to 60 mph, but said it would be faster than the company’s current petroleum performance cars. He also wouldn’t say the range-per-charge for the new Challenger, but added that range isn’t as important as making it a true muscle car. Rick Nelson, the owner of Musclecar Restoration & Design in Pleasant Plains, Illinois, near Springfield, cautioned that switching from loud fuel-burning engines to quiet electricity may be a hard sell to old-timers who grew up with the sounds and smells of racing. Nelson, 61, said he restored his first car while a teenager and spent hours at drag strips. He acknowledged that the switch to electricity is inevitable and is needed to attract a new generation that has become used to quiet speed. Still, he said, electric muscle cars won’t have manual shifters, and he’ll miss the smell of racing fuel at the track. Already, Nelson said, businesses are cropping up to put electric powertrains in classic muscle cars. He has been in touch with an engineer at Tesla about retrofitting batteries and electric motors into some classics.“Guys like me are just going to frown on it and laugh at it,” Nelson said of electric muscle cars. “But this isn’t about my generation.”Kuniskis says the shift to electricity doesn’t mean the end of the muscle car. It’s just a new era. “It’ s OK,” he said. “Let us show you what the future looks like.” Gas-powered muscle cars drive into the sunset & turns electric | MorungExpress | morungexpress.com |

Korean floating SMR design certified (2025-12-24T12:48:00+05:30)

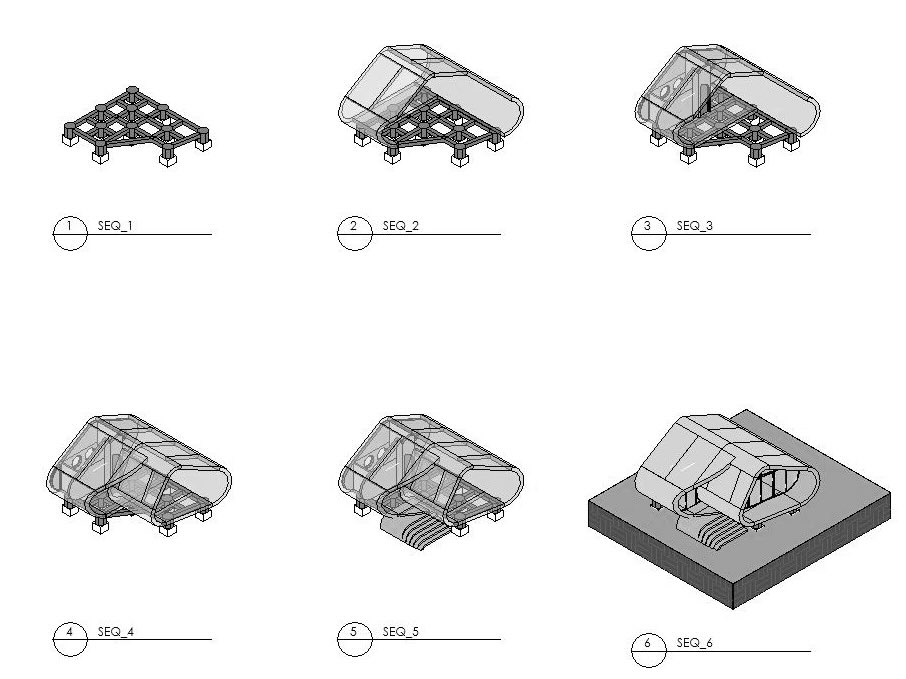

(Image: Korea Atomic Energy Research Institute) (Image: Korea Atomic Energy Research Institute)South Korea's Samsung Heavy Industries has received Approval in Principle from the American Bureau of Shipping for a floating marine nuclear power platform featuring two SMART100 small modular reactors developed by the Korea Atomic Energy Research Institute. As part of the Novel Concept Class Approval process, the American Bureau of Shipping (ABS) grants an Approval in Principle (AIP) at an early conceptual design phase to assist the client in demonstrating project feasibility to its project partners and regulatory bodies. Approval in Principle confirms that the proposed novel concept which includes the new technology complies with the intent of the most applicable ABS Rules and Guides as well as required appropriate industry codes and standards, subject to a list of conditions. Under the certification process, Samsung Heavy Industries was responsible for the integration of the small modular reactors (SMRs) with the floating structure, the overall design of the nuclear power generation facilities, and the development of a multi-barrier reactor containment system. The Korea Atomic Energy Research Institute (KAERI), meanwhile, adapted the land-based SMART100 SMR for offshore applications. Although the Approval in Principle granted by the ABS is for a floating platform incorporating two SMART100 reactors, Samsung Heavy Industries said the concept can be adapted so that different SMR designs can be used. "The FSMR (Floating SMR) is expected to be advantageous for commercialisation as it is a universal floating nuclear power facility model that can be equipped with various types of SMR," the company said. "FSMR is characterised by the application of the so-called 'compartment design', which groups and places the reactor and power generation facilities by function, and by changing the design of only the compartment where the SMR is placed makes it possible to develop FSMR with various types of SMRs applied." In addition, the reactor and safety system - the core components of the floating nuclear power plant - have been modularised within a single containment vessel to enhance safety, and the SMR can be placed within the containment vessel to allow testing on land before being installed on board, thereby shortening the construction period, Samsung Heavy Industries added.  Floating SMR equipped with SMART100 (Image: KAERI) "This AIP is an important milestone for pioneering the offshore nuclear power generation market,” said Ahn Young-kyu, vice president and head of technology development at Samsung Heavy Industries. "Going forward, Samsung Heavy Industries will continue to develop safe and economical offshore nuclear power plants based on its offshore plant technology." Cho Jin-young, head of KAERI's Advanced Nuclear Reactor Research Institute, said: "This acquisition of AIP using SMART100 proves the innovativeness of our nuclear power technology," and added, "We will accelerate technology development so that our country can establish itself as a leading country in the marine nuclear power industry."  (Image: Samsung Heavy Industries) The SMART100 (System-integrated Modular Advanced Reactor 100) is an advanced version of the original SMART design, which became the world's first SMR to receive standard design approval in mid-2012. SMART is a 330 MWt pressurised water reactor with integral steam generators and advanced safety features. The unit is designed for electricity generation (up to 100 MWe) as well as thermal applications, such as seawater desalination, with a 60-year design life and three-year refuelling cycle. The SMART100 builds upon the safety, economic, and operational benefits of the SMART, offering enhanced power output and safety features. SMART100's development prioritised safety improvements, including the integration of a fully passive safety system. This system is capable of maintaining reactor cooling without the need for external power, using natural forces like gravity and fluid density differences to ensure the safe shutdown and cooling of the reactor during emergencies.Along with these safety enhancements, SMART100 also offers increased thermal output, rising from 330 MW to 365 MW, while its electrical output has been boosted from 100 MW to 110 MW, significantly improving efficiency while maintaining a compact design. SMART100 received standard design approval in 2024. Korean floating SMR design certified |

Conceptual design completed for Japan's FAST fusion demo project (2025-12-11T10:56:00+05:30)

(Image: Kyoto Fusioneering) (Image: Kyoto Fusioneering)The Fusion by Advanced Superconducting Tokamak project, designed to demonstrate fusion energy power generation in Japan in the 2030s, has reached its first key milestone, Starlight Engine and Kyoto Fusioneering have announced. The Conceptual Design Report has been put together in the year since the project's launch in November 2024, and involved the two companies and researchers and experts from a number of Japanese universities and public institutions, as well as support from a number of other Japanese companies. The Fusion by Advanced Superconducting Tokamak (FAST) device, to be sited in Japan, aims to generate and sustain a plasma of deuterium-tritium (D-T) reactions, demonstrating an integrated fusion energy system that combines energy conversion including electricity generation and fuel technologies. The project will employ a tokamak configuration, chosen for its well-established data and scalability. Targeting a power generation demonstration by the end of the 2030s, FAST will address remaining technical challenges en route to commercial fusion power plants. The FAST Project Office notes that power generation refers to producing energy from fusion reactions, but does not imply net positive power production where electricity output exceeds electricity consumption. The project team said the conceptual design work involved "designing the fusion energy plant for power generation demonstration, assessing technical and engineering feasibility, clarifying the project direction, conducting safety and economic evaluations, and defining the plant's fundamental design specifications". "With the completion of the conceptual design phase, the project will now shift to engineering design, accelerated engineering R&D, and will proceed with site selection, site preparation, regulatory approvals, and the procurement of long-lead items, with the aim of construction after 2028," it said. Kiyoshi Seko, CEO of Starlight Engine Ltd and President and COO of Kyoto Fusioneering Ltd, said: "Completing the conceptual design in just one year is a result of Japan's decades of research achievement. FAST is now moving into the engineering design phase. We will harness the strength of Japan's manufacturing industry and accelerate the project with a sense of urgency." Satoshi Konishi, co-founder and CEO of Kyoto Fusioneering, said: "First and foremost, it's a great achievement to complete the conceptual design activities within the planned one-year timeframe. We succeeded in creating an innovative design that incorporates new technologies essential for commercial plants, such as high-temperature superconducting magnets, liquid breeding blanket systems, and highly efficient tritium fuel cycle systems, by mobilising domestic experts. Preparations for safety design, regulatory approvals, and site selection are steadily progressing. In the next engineering design phase we expect to fully leverage our strengths in plant engineering and our broad network across diverse industries, including finance and construction." Kenzo Ibano, Assistant Professor, Osaka University, said: "Thanks to the power of industry-academia collaboration, we have successfully produced Japan’s first CDR for a power generation demonstration project. Working alongside researchers with decades of experience and private-sector partners in driving this project forward is both stimulating and rewarding, giving a strong sense of mission." The Conceptual Design Report is due to be presented at the 42nd Annual Meeting of the Japan Society of Plasma Science and Nuclear Fusion Research being held from 1 December.Other academics and businesses participating in and supporting the FAST project include Professor Akira Ejiri, University of Tokyo and Professor Takaaki Fujita, Nagoya University, as well as Sumitomo Mitsui Banking Corporation, Electric Power Development (J-Power), JGC JAPAN Corporation, Hitachi, Fujikura, Furukawa Electric, Marubeni Corporation, Kajima Corporation, Kyocera, Mitsui & Co., Mitsui Fudosan, and Mitsubishi Corporation. Conceptual design completed for Japan's FAST fusion demo project |

Bamboo Panels on World’s Longest Sea Crossing Withstand 6 Years of Sun and Typhoons–Still Solid as Ever (2025-10-31T12:16:00+05:30)

DassoXTR bamboo decking along the Chinese coast, like the kind used on the world’s longest sea crossing – credit: Dasso USA DassoXTR bamboo decking along the Chinese coast, like the kind used on the world’s longest sea crossing – credit: Dasso USAReprinted with permission from World at Large. Six years after their installation on the world’s longest sea crossing, thousands of bamboo panels have withstood six years of intense exposure to the elements without issue. A report published by engineers in the Chinese paper Science and Technology Daily claims the panels are “as solid as ever,” a mark of success for China’s blossoming bamboo engineering industry, where the world’s fastest-growing plant is becoming its fastest-growing construction material. While walking last spring through the city of Lucknow, India, I saw a tall concrete water tower under construction. The concrete was clearly setting; it was that dark grey color typical of wet cement, and every right angle was sharp as a knife edge. I was left in utter shock as every square foot of structure all the way up to the basin at the top was supported by a half-dozen tall trunks of bamboo. Hundreds of them had been used, and they cluttered the future water tower like an artistic child’s popsicle stick sculpture. It was a sight endemic to Asia—the home of bamboo, undoubtedly one of the world’s most remarkable plants. This member of the grass family contains more than 1,400 species spread out over 115 genera, including some which can grow over a meter a day. But speed isn’t bamboo’s only characteristic. Some species display a tensile strength similar to steel. Some match up with hardwood lumber, and others far surpass concrete for PSI. It loves marginal land, sequesters 50% more carbon dioxide than typical trees, and some bamboo species even spark like flint when struck with an axe. These properties make bamboo a rapidly emerging material for so much more than just the eco-friendly cutting board or bedspread you saw in IKEA.  A section of the Hong Kong–Zhuhai–Macau Bridge terminating at the entrance to an undersea tunnel – credit Am730, retrieved from YouTube. CC 3.0. Besting the elements The Hong Kong-Zhuhai-Macau Bridge is the world’s largest and longest sea crossing and is described sometimes as one of the Seven Wonders of the Modern World. It consists of three cable-stayed bridges, four artificial islands, and an undersea tunnel all of which cover 34 miles (55 kilometers) of open sea beyond the Pearl River Delta. Stretching for many miles along these installations, the scenic observation platforms are lined in 215,000 square feet of DassoXTR bamboo floor panels that have withstood sunlight, typhoons, and seawater corrosion, remaining “as solid as ever,” according to the report in the Daily. These panels have been specially engineered to act as composite building materials through an innovative heat treatment to remove the tendency of bamboo to rapidly decay due to its rich nutrient stores. Lou Zhichao, from Nanjing Forestry University’s Bamboo Research Institute, has been working on treatments like these to improve bamboo’s versatility and durability. The heat treatment was perfected in 2016, but since then his institute has developed a low-emission adhesive with reduced formaldehyde and phenol levels specifically designed to create composite bamboo products while adhering to strict emissions codes for the European market. “China is not only the world’s largest bamboo producer but also holds a comparative advantage in processing capabilities,” Lou told the Daily, which added the total Chinese market is worth around $74.2 billion. “Maintaining China’s leadership in bamboo technology innovation is crucial. The industry should focus on advancing automation and smart manufacturing while actively shaping international standards.”In 2023, China announced a three-year plan to promote “bamboo instead of plastic,” to increase bamboo utilization by 20% by 2025 in an effort to reduce plastic waste. That means more bamboo in everything from construction to packaging. Bamboo Panels on World’s Longest Sea Crossing Withstand 6 Years of Sun and Typhoons–Still Solid as Ever |

Innovative New 'Sponge' Park Helped Save Historic Atlanta Neighborhood from Flooding (2025-09-30T11:50:00+05:30)

Rodney Cook Sr. Park in Vine City – credit, HDR inc. Rodney Cook Sr. Park in Vine City – credit, HDR inc.$40 million may seem like a lot of money to the average person, but it’s just a fraction of what municipalities were spending to cleanup and shore-up their cities and towns following Hurricane Helene. For Vine City, Atlanta, $40 million was the cost of a solution to flooding problems that long predate Helene. It bought the historic neighborhood a big, beautiful new park that works like a sponge. GNN has reported on the “sponge city” concept before, whereby parks and urban developers use greenery and water features to help absorb rain and floodwater to slow its entry into the drainage system. It’s been picked up by the Netherlands and China, and now too, in Atlanta with Rodney Cook Sr. Park. Atlanta City Council member Byron Amos, who was born and raised in Vine City, remembers several flooding events that left residents’ basements submerged and cars soaked through. Amos worked with the Trust for Public Land to adopt the sponge city concept for Vine City. “When water is rerouted through the neighborhood to this site, the pond fills up, and the rain gardens, other green infrastructure throughout the park houses water to be collected and basically take the load off the city’s stormwater system,” said Jay Wozniak with the trust. Despite being 300 miles inland, Helene reached out her stormy fingers even as far as Atlanta, and suddenly, Amos and Woziank’s solution would be put to the test. “People were calling, ‘The park is flooding! The park is flooding!’ and my response was, ‘It’s doing its job,” Amos told CBS News. Indeed, Rodney Cook Park filled up with 9 million gallons of water, but nearby residents’ homes stayed dry. Within 72 hours, Wozniak said, no one even knew a storm had taken place. In addition to being a piece of the stormwater system, the park is also a beautiful gathering space filled with water features, a multi-sport composite court, plenty of green spaces, and fitness equipment.Built for the trust by HDR, it collected no less than 10 major architecture, design, and landscape engineering awards. Innovative New 'Sponge' Park Helped Save Historic Atlanta Neighborhood from Flooding WATCH the story below from CBS… |

Arizona Suburb Turned into Mediterranean-style Walking Town Where Temperatures Stay Low (2025-09-29T11:40:00+05:30)

– released as a courtesy by Culdesac A planned community in Arizona has used time-honored Mediterranean strategies to keep temperatures down and attitudes high. Western civilization has grown remarkably climate conscious over the last 20 years, but not when it comes to building, civic planning, and especially zoning. Perhaps the interiors of buildings are becoming more climate adapted, and in some cases the facades as well, but in a way that’s a little like inventing a freezer designed to keep ice cream frozen while sitting next to a fire. Wooden or concrete boxes arranged side-by-side across leveled ground with sprawling, largely treeless gardens and concrete sidewalks alongside wide, blacktop roads is simply a culture of construction that has to be abandoned if living in a world of 2°C or higher annual temperatures is to be tolerable. Fortunately for Arizonans, change may have finally arrived in the form of a carless, planned community that looks and feels like a Greek island village. In the Phoenix suburb of Tempe, Culdesac has arisen as a 17-acre mixed-use neighborhood from the ground up to stay cool and local, taking the concept of the 15-minute city, where anything a resident might need is only 15 minutes away, and putting a Mediterranean spin on it. Buildings are tall, thick, and totally white. The residential areas look like they were built atop of the ashes of the Phoenix zoning code burnt in effigy. Crammed together, they create narrow streets and alleys that are almost constantly shaded, through which wind is channeled and accelerated in passing. Windows open towards each other, allowing wind that enters one building to exit into another, while the total lack of asphalt means that the ground temperatures are a staggering 50-60°F lower than pavements beyond the limits of Culdesac. No privately-owned cars are allowed to enter the neighborhood, in which electric bikes, robotic mini taxis, and light rail shuttle people around town, to downtown Phoenix, or out to the airport. The street life is lively—there are no cars to bisect movement between the 21 different businesses and eateries, among which is a James Beard Award-winning Mexican restaurant, DIY ceramic business, and some stores run out of apartments—a big no-no under Phoenix zoning laws. “Once you pull the cars out,” Architect Daniel Parolek who designed Culdesac, told BBC, “there’s so much more opportunity to make a vibrant, thriving community.” His inspiration was sun-soaked locales like Italy, Greece, and Croatia, where town centers were designed before the automobile and before air conditioning. Technically speaking, the entire Culdesac neighborhood is one apartment complex, but the paseos, or little alleyways, open up into plazas of open space exactly liked one would expect in a little village in the Cyclades. Because no one has to jump in a car to get from place to place, people run into each other, sparking conversations, relations, and breaking through the counterintuitive phenomenon of big city loneliness, which in Phoenix hits particularly hard.“Culdesac Tempe has shown that people do want to live car-free in the US, even in a metro area like Phoenix that’s often seen as the poster child for car dependency,” says Erin Boyd, Culdesac’s government relations and external affairs lead. “This success has shifted the conversation around what’s possible in American development.” Arizona Suburb Turned into Mediterranean-style Walking Town Where Temperatures Stay Low - Good News Network |

Stylish Prefab Home Can Be ‘Dropped’ into Flooded Areas or Anywhere Housing is Needed (2025-09-17T13:25:00+05:30)

Drop Pod tiny homes – Courtesy of Inspiral Architecture and Design Studios Drop Pod tiny homes – Courtesy of Inspiral Architecture and Design StudiosCreated for our changing climate and rising sea levels, architects in the island nation of Indonesia designed the Drop Pod, a modular structure that is “quick to distribute and easy to install.” The futuristic prefabricated homes developed by Inspiral Architecture and Design Studios are designed to be both stylish and expandable, with the ability to be placed on a variety of terrain and deployed rapidly. “Whether it’s an urban area in a wealthy country or a developing country battling climate change, the Drop Pod provides the solution,” says the company’s website. “Nowadays, we see ourselves more and more confronted with issues of constant population growth and major changes in our climate.” For decades, sea levels have risen about 8 millimeters per year, according to a video report shot in Indonesia by Al Jazeera. This has caused major flooding and tidal surges that have consumed thousands of homes. Drop Pod saw the need for a house that is quick to distribute and easy to install. Their goal was to provide a tiny house that is both user and environmentally friendly.  Courtesy of Inspiral Architecture and Design Studios Courtesy of Inspiral Architecture and Design Studios Courtesy of Inspiral Architecture and Design Studios Courtesy of Inspiral Architecture and Design Studios“The design provides a quality space that can be built in one week,” claims the firm. And, the stone foundation, which elevates the home above potential floodwaters also allows the structure to be placed on sloped terrain with ease.  Inspiral Architecture and Design Studios Inspiral Architecture and Design StudiosThe shell of the structure stands on a footing of 1.2 meters high (about 4 feet), allowing for flood resistance and is easy to add-on additional wings for more space. Despite its diminutive size, the home emits a light and airy feeling with its light wood finish and mirrored wall. Built-in shelving helps solve storage issues, while steps lead to a bedroom loft overlooking the living space. The glass front can be fitted with large curtains to provide privacy. The bathroom and bedroom follows the same principle, combining practical layouts with design detail such as rounded windows and integrated cabinetry.  Courtesy of Inspiral Architecture and Design Studios Courtesy of Inspiral Architecture and Design StudiosThe first Drop Pod prototype has been installed in West Nusa Tenggara, Indonesia, and, if nothing else, it shows us that “prefab doesn’t have to mean boring”. We’ve reached out to Inspiral to inquire about the price, because it’s not listed online. See more photos of the home on their website… Stylish Prefab Home Can Be ‘Dropped’ into Flooded Areas or Anywhere Housing is Needed |

Dutch Designers Create Tiny Home by Burrowing into the Bosom of a Recycled Wind Turbine (2025-09-10T12:21:00+05:30)

The Nestle, made from a wind turbine – credit, Jorrit Lousberg / Blade-Made For some, a 4 bedroom 3 bath with a basement theater, wrap-around deck, and two-car garage is the dream. For others, housing that’s quaint, that’s economical—even portable, is the aim. The market should provide options to everybody, and for those in the latter category of taste, a Dutch company is making little trailer-sized homes from the bosoms of decommissioned wind turbines. Known as a Nestle—a play on words referring to the turbine component known as a “nacelle”—this two room human hutch is surprisingly luminous and chic. The 35-square-meter (376-square-foot) pods are built by a company called Blade-Made that uses decommissioned wind turbine parts that are impossible to recycle as materials to build new structures like benches, highway barriers, playgrounds, and even housing. Inside, a warm north-European wooden finish on the walls and furnishings embody the project’s name, and help convince the occupant to nestle into Nestle’s living space. Perhaps designed more as a statement on the challenges and potential of upcycling rather than as a direct-to-market product, Blade-Made has nevertheless received orders for 10 of these nacelle homes, having been certified by Dutch authorities under the nation’s building codes.  Nestle’s interior is light and airy, with fully functional plumbing and electricity – credit, Jorrit Lousberg / Blade–Made Nestle’s interior is light and airy, with fully functional plumbing and electricity – credit, Jorrit Lousberg / Blade–Made“Everything in the built environment—everything that you see around you—has an end of life,” Blade-Made’s Jos de Krieger told CNN Style via videocall. “And we need solutions besides waste or landfill, incineration or something without value.” A challenge facing wind energy is the millions of pounds of fiberglass-heavy material that cannot be recycled but which nevertheless must be replaced every few decades. The initial wind turbine boom has seen its first wave of mass decommissioning, and hundreds of thousands of tons of nacelles and blades will need new homes or purposes. “This is basically the most complex thing that you can do with it,” said De Krieger, who’s also a partner at the architecture firm Superuse Studios, one of the home’s designers. “So, all the other less complex things are now easier to imagine and to realize, because this has already been done.” Many partners were involved with the debut Nestle. Woodwave build the interior, which was designed by Superuse and Reliving.nl. Business in Wind provided the decommissioned V80 turbine nacelle for use in the first model, which was sponsored by Swedish power company Vattenfall. By 2050, no doubt hundreds of nacelles will be in need of replacing every month across Europe and the world, and every one of them becoming a home seems doubtful. But as is so often the case, design helps us reimagine the potential of many different things, and if by 2050 there are hundreds of people living in Nestles, humanity stands only to benefit. Dutch Designers Create Tiny Home by Burrowing into the Bosom of a Recycled Wind Turbine |

This Home Siding Made from Rice Husks Saves Thousands of Trees and Diverts Crop Waste from Landfills (2025-08-13T13:16:00+05:30)

ACRE siding on a home – credit, Modern Mill, supplied ACRE siding on a home – credit, Modern Mill, supplied13/08/2025, A groundbreaking new material made from upcycled rice husks in a zero-waste environment is giving homebuilders the option to reduce their carbon footprint while adding a rustic charm to their home’s exterior. The product, called ACRE, offers the warmth and beauty of real wood with all the conveniences of composites, and is available as siding, decking, fencing, sheets, and trimming. If any Americans were following the news during trade negotiations between Japan and the US, they may have learned, and maybe were surprised to do so, that US farmers grow 20 billion pounds of rice every year. Each of those pounds are made up of hundreds of individual rice grains, each of which is covered by a hard husk, sometimes called a hull, which are normally just sent to the landfill. ACRE inventor and producer Modern Mill is changing that by transforming this overlooked byproduct into a high-performance wood replacement that doesn’t require cutting down a single tree, and they’ve already spared 4,000 tons of rice husks from the landfill. Unlike wheat, the rice hulls contain a significant amount of lignin, the organic polymer that forms wood. This makes them strong and durable when processed, and capable of being harnessed for use as a building material. The husks themselves offer a tone and depth of color that the company describes as imitating tropical hardwoods like teak, ipe, and cedar.  An ACRE board – credit, Modern Mill, supplied One pallet of ACRE material, therefore, saves a whole acre of tropical rainforest hardwoods, and in 2022 alone, 44,000 of those pallets were delivered to builders around the country. Though prices can vary significantly, for most building projects their siding will cost between $10 and $12 per square foot. In 2023, Modern Mill was named to Fast Company Magazine’s Most Innovative Companies list, and in 2025, in response to the devastating Palisades fires in California, Modern Mill donated siding for 20 families who lost their homes to aid recovery and rebuilding efforts. “Our hearts are with the families and communities affected by the wildfires,” said Chris Guimond, Chief Executive Officer at Modern Mill. “We’re doing everything we can to help support relief efforts.”ACRE is tested and certified in accordance with California fire code to be used in all areas from moderate to very high fire hazard severity. This Home Siding Made from Rice Husks Saves Thousands of Trees and Diverts Crop Waste from Landfills |

ABS approves second Korean floating SMR plant design (2025-07-23T12:45:00+05:30)

_65954.jpg) Kwang-Sik Won, Senior Executive Vice President of HD HHI Offshore Business Division (left), with Patrick Ryan of ABS (Image: ABS) Kwang-Sik Won, Senior Executive Vice President of HD HHI Offshore Business Division (left), with Patrick Ryan of ABS (Image: ABS)Maritime classification society the American Bureau of Shipping has issued approval in principle to HD Hyundai Heavy Industries and HD Korea Shipbuilding & Offshore Engineering for a concept of a floating small modular reactor-powered power module. The design developed by HD Hyundai Heavy Industries (HHI) and HD Korea Shipbuilding & Offshore Engineering is intended to generate electricity offshore and near shore, supporting port facilities and onshore communities. The American Bureau of Shipping (ABS) completed design reviews based on the ABS Requirements for Nuclear Power Systems for Marine and Offshore Applications. Launched in October 2024, ABS says these are the industry's first comprehensive rules for floating nuclear power plants. At the time of the launch, ABS noted it is the responsibility of nuclear regulators to license the reactor and applicable nuclear safety structures, systems and components. As part of the Novel Concept Class Approval process, ABS grants an Approval in Principle at an early conceptual design phase to assist the client in demonstrating project feasibility to its project partners and regulatory bodies. Approval in Principle confirms that the proposed novel concept that includes the new technology complies with the intent of the most applicable ABS Rules and Guides as well as required appropriate industry codes and standards, subject to a list of conditions. "Floating nuclear power facilities show promise in supporting power grids, microgrids, industrial and port operations, data centres, and other uses," said Patrick Ryan, ABS Senior Vice President and Chief Technology Officer. "Additionally, today's advanced nuclear technology has a different risk profile from traditional reactor technology with state-of-the-art designs and with lower enrichment fuels, making commercial offshore and maritime applications more viable." An HD Korea Shipbuilding & Offshore Engineering spokesperson said: "The floating nuclear power plant is expected to play a key role in building a future powered by clean energy. We will remain fully committed to developing the necessary technologies and ensuring its successful realisation." This is the second Approval in Principle for a floating nuclear power barge design granted to HD Korea Shipbuilding & Offshore Engineering by the ABS. In October 2023, it issued Approval in Principle for a floating offshore nuclear power barge intended to serve as offshore power generation for remote communities and island electrification. HD Korea Shipbuilding & Offshore Engineering previously obtained approval in principle from the ABS for a 15,000 TEU-class container ship design model applying small modular reactor (SMR) technology.In February this year, HD Korea Shipbuilding & Offshore Engineering unveiled another nuclear-powered container ship model utilising SMR technology. It said the new design model features enhanced economic efficiency and safety by incorporating actual equipment and safety design concepts. ABS approves second Korean floating SMR plant design |

E-bikes for everyone: 3 NZ trials show people will make the switch – with the right support (2025-06-26T10:55:00+05:30)

|

Caroline Shaw, University of Otago; Karen Witten, Te Kunenga ki Pūrehuroa – Massey University, and Simon Kingham, University of Canterbury Anyone who uses city roads will know e-bikes have become increasingly popular in Aotearoa New Zealand. But we also know rising e-bike sales have been predominantly driven by financially well-off households. The question now is, can e-biking be accepted and embraced by people and communities where it is currently not happening? Three pilot programmes from around the country have now given us cause for optimism. Understanding more about the barriers to e-bike access – especially in communities with low cycling levels or where income levels mean bikes are prohibitively expensive – has been one of the main gaps in our knowledge. But over the past few years, we have been involved in projects designed to examine how e-bikes might work in such places. The three pilots were based in Mangere (South Auckland), Wainuiomata (Lower Hutt) and Sydenham (Christchurch). These are all areas or communities with lower relative incomes and lower levels of cycling. The majority of individuals involved did not routinely cycle, and some hadn’t been on a bike for decades. In all three pilots, the results were positive. In some cases, participants reported long-term, life-changing benefits. What the pilot schemes showedEach pilot was different. The Mangere programme loaned e-bikes to people for two to three months between 2022 and 2023 through a community bikehub. The Wainuiomata programme involved a longer loan period of one year over 2023, and was run through a health provider at a local marae. The Christchurch programme, which ran between 2021 and 2024, was a free e-bike share scheme for tenants in a specific social housing complex, organised through a partnership with a shared e-bike provider. Where needed, participants in all pilots were supported as they gained riding confidence and knowledge of safe cycling routes. Participants in all the pilot programmes found e-biking acceptable, and they used and enjoyed the bikes. While these pilots were not set up to measure distance travelled, we know from other research that participants in e-bike access schemes ride on average 5km per day, half of which replaces car trips. Individuals reported practical benefits such as being able to travel to their jobs, mental and physical health improvements, and not having to pay for petrol each week. In the Wainuiomata pilot there were wider ripple effects, with participants reporting whānau members also started cycling as a result of the loan scheme. In one case, ten members of the wider whānau got involved. 3 policy actions needed nowThese results mirror what we know already about how e-bikes can improve physical and mental health, reduce transport greenhouse gas emissions, and make cities nicer places by reducing car use. Compared to conventional bikes, e-bikes also allow people to bike further and in hillier places. They are also great for groups with traditionally lower levels of cycling, such as people with health conditions, disabilities, older people and women. It also seems concerns about increased rates of injury may be less significant than initially thought. Overall, the broad benefits of e-bikes have seen hundreds of access schemes developed globally, including many in New Zealand. Combining international evidence and experience with the information from the three local pilot programmes, we see three main policy areas that will increase e-bike uptake and use in New Zealand. 1. Physical infrastructure: this is needed to support cycling in all our cities and larger towns, and would involve a combination of cycle lanes and low-traffic neighbourhoods, alongside expanded bike parking and storage. The Climate Change Commission has recommended these networks be constructed, and experience from Wellington shows rapid construction is possible. 2. Targeted access schemes: these help people who can’t afford e-bikes. Without targeting, such schemes tend to be mainly used by the well-off. It’s likely we will need a range of options, such as short-term and long-term low-cost (or free) loans, rent-to-buy schemes or subsidies. People should be able to access these schemes through a variety of organisations so as to target different motivations: saving money, improving health, commuting for work, ferrying children, environmental concern. 3. Local organisation networks: these support individuals and communities to access bikes, maintain them, provide rider training, run bike libraries, route finding and community events to support and encourage people to ride. This wider support was a key factor to the success of the all pilots. Local organisations, champions and leaders are essential to help overcome some of the practical and cultural barriers that exist because we have such low levels of cycling. Change is achievableWhat we have outlined constitutes a different way of doing business for the transport sector. But there are already organisations doing a lot of this work, including bike hubs and cycling community organisations. Others have infrastructure in place that could expand to encompass e-bike programmes, such as marae and community health centres. What is needed is a commitment to support these activities as part of core transport business policy. We don’t need to wait for more research. The three things required – building infrastructure, increasing access and providing support programmes – are all understood and achievable. E-bikes can and should play an important role in expanding New Zealand’s transport options and improving the wellbeing of its people. Caroline Shaw, Associate Professor in Public Health, University of Otago; Karen Witten, Professor of Public Health, Te Kunenga ki Pūrehuroa – Massey University, and Simon Kingham, Professor of Human Geography, University of Canterbury This article is republished from The Conversation under a Creative Commons license. Read the original article. |